When selecting RF connectors for your business, understanding the difference between MCX and MMCX is crucial. For instance, an mmcx connector female is a key component in many compact devices, and knowing its role versus an MCX connector can impact your project’s success. This article explores these connectors, compares their features, and guides you to the right choice for your B2B needs, incorporating solutions like custom mmcx cables and mmcx sma adapters.

What Are MCX and MMCX Connectors?

When selecting between MCX and mmc connectors – both snap-on types for RF applications – businesses must evaluate critical differences in size, performance, and durability. MCX connectors provide robust durability for frequent connections, while mmc connectors deliver a 30% smaller footprint for space-constrained designs with reliable performance up to 6 GHz. This distinction becomes essential when implementing mcx to mmcx solutions, where mechanical stability and consistent signal integrity in dense layouts are paramount. Understanding these technical trade-offs ensures optimal reliability in wireless communications, IoT devices, and test equipment deployments, while addressing common challenges like connector wobble and field failure in compact systems.

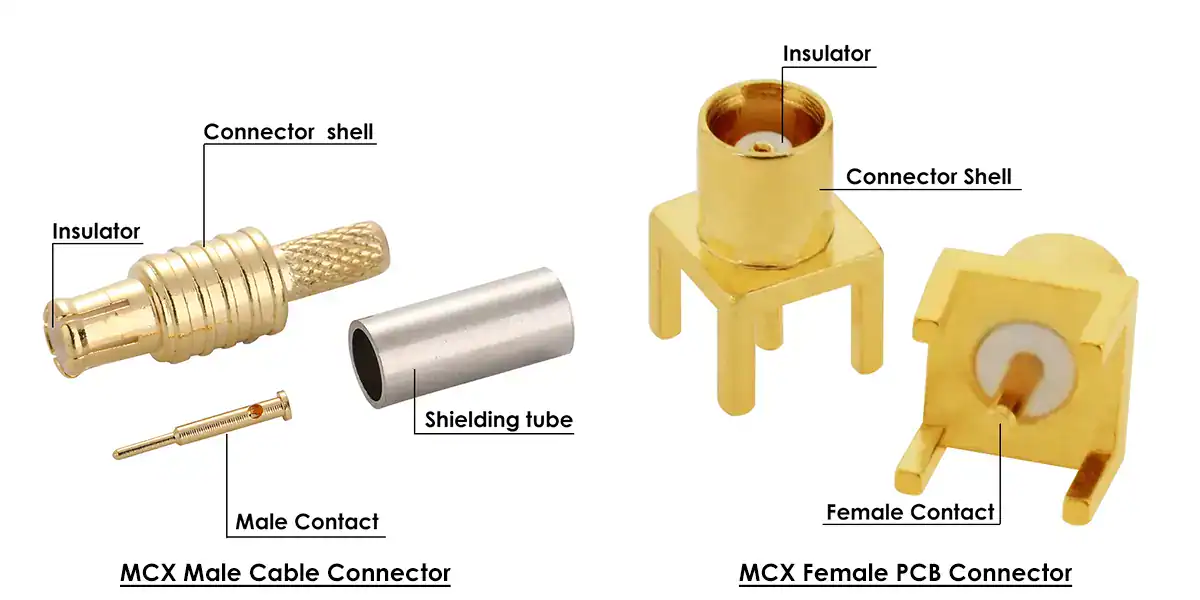

Understanding MCX Connectors

MCX to RF connector solutions deliver a compact form factor with a 3.5 mm diameter interface and broadband performance up to 6 GHz, making them ideal for GPS modules, wireless communication systems, and larger antenna assemblies where space efficiency is critical. The mcx coax connector design supports robust signal integrity and stable RF performance in demanding industrial and telecom environments, thanks to its snap-on mechanical coupling for quick mating and reliable retention. These products simplify inventory and assembly processes by enabling short, standardized cable runs and easy field installation using mcx plug with cable options, which reduces custom harness costs and accelerates integration for OEMs and system integrators. Stocked mcx connector antenna variants and rapid ship services from ZOMWAVE help cut lead times and support production scaling without sacrificing durability or electrical specs. Additionally, the mcx coax connector addresses vibration resistance and environmental adaptability, ensuring long-term reliability and minimal maintenance in infrastructure deployments where consistent connectivity is essential.

Understanding MMCX Connectors

MMCX connectors, with a compact 2.5 mm diameter, are engineered for extremely tight spaces and high-density applications. Paired with an mmcx male connector or an mmcx connector female, these reliable mmcx connector types are commonly utilized in headsets, small antennas, and portable devices. An MMCX connector cable or custom mmcx cable is ideal for low-power, high-frequency scenarios where minimal size and weight are critical. These connectors provide enhanced durability with up to 500 mating cycles, superior vibration resistance, and stable performance in challenging environments, helping OEMs streamline assembly, reduce total cost of ownership, and accelerate time-to-market for compact consumer and IoT solutions.

Analyzing the Key Differences

To solve the MCX vs. MMCX dilemma, let’s analyze their distinctions:

- Size: MCX (3.5 mm) is larger than MMCX (2.5 mm), affecting where they can be used.

- Power and Frequency: MCX handles higher power and up to 6 GHz, while MMCX is suited for lower power setups.

- Applications: MCX fits broader RF uses; MMCX excels in compact, space-limited designs.

These differences impact compatibility with tools like an mmcx sma adapter or a custom mmcx female cable.

Solving the Selection Challenge

Choosing between MCX and MMCX depends on your project’s needs:

- Space-Constrained Projects: Opt for MMCX connectors. Their small size and options like mmcx cables make them perfect for compact devices.

- High-Performance Needs:Choose MCX cables for applications requiring higher power handling and a wider frequency range.

- Compatibility: Need to adapt? An mmcx sma adapter bridges MMCX setups to other systems seamlessly.

Why This Matters for Your Business

Selecting the appropriate connector is critical for product reliability and long-term cost efficiency in manufacturing and industrial applications. A precise grasp of mmcx connector dimensions and mating tolerances prevents signal degradation, reduces rework, and lowers lifecycle expenses by minimizing field failures and simplifying warranty management. Whether your design requires an mmcx female connector for ultra-compact layouts or a robust mcx female to rf connector for durable interfacing, evaluating mechanical specifications, impedance stability, and shielding effectiveness ensures informed procurement and efficient assembly. Available solutions include standard mcx antenna options, custom mmcx cables, and versatile interconnects such as mcx to smp cable, mcx to mcx cable, and mmcx to smp cable to address enclosure limitations and RF design budgets. These options help simplify inventory management, accelerate validation cycles, and mitigate integration risks, while additionally solving challenges like space optimization, cross-platform compatibility, and maintenance overhead through field-proven, durable designs. Contact us for customized connector and cable assemblies tailored to your specific requirements.

Coaxial Cable Assembly

Coaxial Cable Assembly Microwave Test Cable

Microwave Test Cable Coaxial RF Connector

Coaxial RF Connector Coaxial RF Adapter

Coaxial RF Adapter Coaxial RF Termination

Coaxial RF Termination Coaxial RF Test Probe

Coaxial RF Test Probe Coaxial RF Attenuator

Coaxial RF Attenuator RF Switches

RF Switches Rotary Joints

Rotary Joints Coaxial RF Power Dividers

Coaxial RF Power Dividers

Excellent article! MMCX and MCX connectors are a crucial part of any wireless system, ensuring minimal signal loss and strong connectivity. At Eteily Technologies, we design and manufacture a wide range of RF connectors including SMA, TNC, N-type, and MCX — all engineered for high durability, low VSWR, and superior performance across communication applications

Awesome

Great information!