In the intricate world of radio frequency (RF) connectivity, the humble MMCX connector female socket plays a critical, yet often underappreciated, role. While the MMCX male connector on a cable or device grabs attention, it’s the female receptacle that faces the relentless stress of mating cycles, mechanical strain, and environmental factors. For engineers sourcing components for critical communication systems, test equipment, or IoT devices, a pressing question arises: What is the true durability of the MMCX connector, specifically its female counterpart, and how can we ensure long-term reliability? Understanding this is paramount, as RF MMCX performance hinges directly on the integrity of this connection point. Failure means signal loss, intermittent faults, and costly downtime.

The Fragile Point: Why the MMCX Female Socket Demands Attention

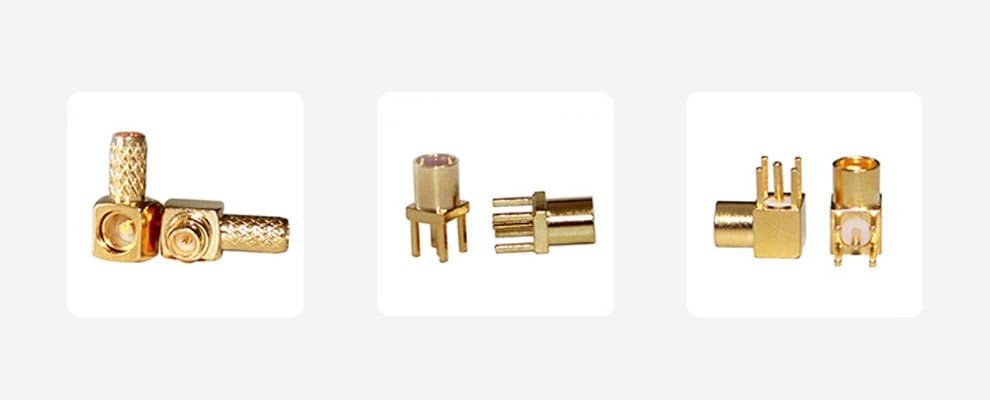

Unlike bulkier counterparts (SMA, N-Type), the MMCX’s miniaturization brings inherent challenges to durability, concentrated significantly within the female mmcx connector jack:

Contact Spring Fatigue

The heart of the mmcx connector female is its delicate internal spring contact. Every insertion of the MMCX male connector deflects this spring. Over hundreds or thousands of cycles, metal fatigue sets in. The spring loses its tension, leading to poor electrical contact, increased insertion loss, and degraded VSWR – disastrous for radio frequency MMCX signal integrity.

Wear & Contamination

Friction during mating wears down the plating (often gold over nickel) on both the male pin and the female mmcx socket contacts. Abrasive dust or contaminants accelerate this. Worn plating exposes base metals, increasing oxidation and resistance. For rf mmcx links, even minor resistance spikes cause measurable signal degradation.

Shell & Insulator Damage

Improper mating (off-axis insertion, over-rotation) or excessive cable pulling can physically damage the thin outer shell of the receptacle or crack the internal dielectric insulator. This compromises mechanical stability and potentially shorts the center conductor.

Solder Joint Integrity

The female mmcx pcb connector relies on solder joints to the circuit board. Mechanical stress from cable tugging or thermal cycling can fracture these joints, causing intermittent or complete failure – a common, often overlooked failure mode impacting mmcx connector durability.

Quantifying MMCX Durability: Beyond the Basic Spec

Manufacturers typically advertise a standard rating of 500 mating cycles for MMCX connectors. However, treating this as a universal guarantee is a mistake for B2B buyers. Real-world mmcx female jack longevity depends heavily on:

- Manufacturer Quality & Materials (H3): Premium suppliers use high-grade beryllium copper or phosphor bronze for springs, thicker/higher purity gold plating, and robust engineering thermoplastics for insulators. Cheaper alternatives sacrifice these, drastically reducing rf mmcx connector lifespan under identical conditions.

- Precision Machining (H3 – Long Tail): Tight tolerances in the mmcx receptacle socket ensure proper pin alignment and spring deflection. Loose machining causes uneven wear and premature failure.

- Application Conditions (H3): Will the mmcx cable experience constant vibration? Extreme temperatures? Humidity or chemical exposure? Harsh environments accelerate all degradation mechanisms. An mmcx connector rated for 500 cycles in a benign lab might fail at 100 cycles on a vibrating outdoor antenna.

- Handling & Mating Practices (H3): Forceful insertions, misalignment, or frequent unplugging significantly shorten mmcx female connector service life. Proper handling is crucial.

Selecting & Specifying for Maximum MMCX Female Longevity

Ensuring reliable mmcx connector female performance requires a proactive, specification-driven approach:

- Demand Higher Cycle Ratings (H3): Don’t settle for the bare minimum 500 cycles. Seek manufacturers specifying 1000 cycles or more for their high-cycle mmcx female connectors. This indicates superior materials and construction.

- Prioritize Material Specifications (H3):

- Spring: Request BeCu (Beryllium Copper) for optimal fatigue resistance over cheaper phosphor bronze.

- Plating: Specify thick gold plating (e.g., 50 microinches min) over a robust nickel barrier layer to prevent wear-through and oxidation, critical for stable rf mmcx impedance.

- Insulator: Ensure high-temperature, stable dielectrics like PTFE or PPS, especially for rf mmcx applications.

- Require Precision Machining Certifications (H3 – Long Tail): Ask for evidence of dimensional conformance to IEC 60169-38 standards for precision mmcx jacks. This ensures consistent mating and contact.

- Consider Application-Specific Designs (H3):

- Strain Relief: For cable-mounted sockets (mmcx female bulkhead connector), robust strain relief is non-negotiable to prevent solder joint failure and cable pull-out.

- PCB Mounting: For female mmcx pcb connectors, choose designs with reinforced solder tabs or through-hole options for better mechanical strength versus surface-mount-only.

- Environmental Sealing: If needed, specify IP-rated mmcx receptacles (e.g., IP67) using silicone seals to block moisture and contaminants.

- Enforce Strict Handling Protocols (H3): Train personnel on correct mating/unnmating procedures (straight insertion, minimal rotation, no pulling on the mmcx cable). Use protective caps when unmated. Implement connector inspection schedules.

Conclusion: Durability is a Specification, Not Luck

The durability of an MMCX connector female socket is not a fixed number; it’s the result of deliberate engineering choices, stringent manufacturing, and careful application management. While the miniaturization essential for modern radio frequency mmcx systems presents challenges, understanding the failure mechanisms – primarily spring fatigue, wear, and mechanical damage – empowers buyers. By demanding higher cycle ratings, superior materials (BeCu springs, thick Au plating), precision machining, and application-appropriate features (robust strain relief, environmental sealing), you move far beyond the baseline 500 cycles.

Investing in truly durable mmcx female connector components translates directly into reduced field failures, lower maintenance costs, and sustained high-performance RF links. Don’t gamble on connector longevity – specify it precisely. Request certified test reports and detailed material specifications from your MMCX supplier to ensure your critical RF connections are built to last.

Request MMCX Durability Specifications & Test Reports

Coaxial Cable Assembly

Coaxial Cable Assembly Microwave Test Cable

Microwave Test Cable Coaxial RF Connector

Coaxial RF Connector Coaxial RF Adapter

Coaxial RF Adapter Coaxial RF Termination

Coaxial RF Termination Coaxial RF Test Probe

Coaxial RF Test Probe Coaxial RF Attenuator

Coaxial RF Attenuator RF Switches

RF Switches Rotary Joints

Rotary Joints Coaxial RF Power Dividers

Coaxial RF Power Dividers